A Closer Look at Live Tooling Strategies in Swiss Machining

Table Of Contents

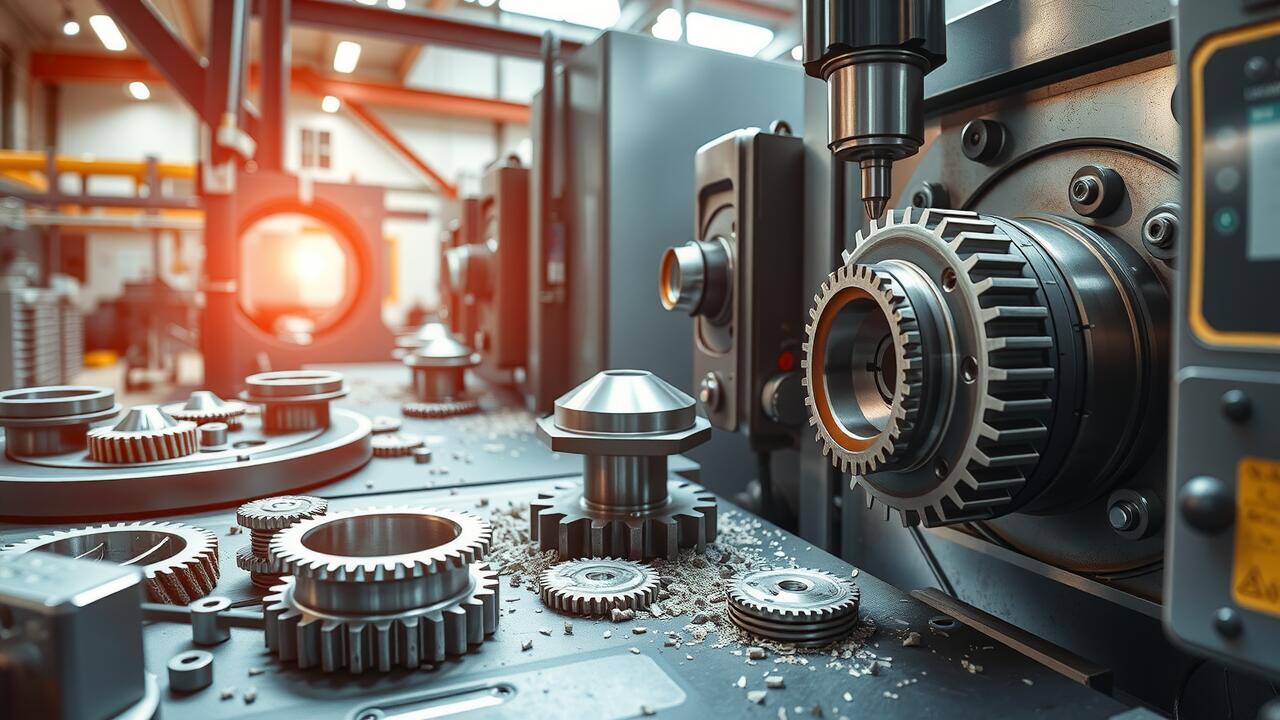

Maintenance Tips for Live Tooling Equipment

For optimal performance in cnc swiss machining, keeping live tooling equipment well-maintained is a must. Regularly inspect tool holders and drive systems for any wear or backlash. Even the smallest misalignment can lead to significant deviations in part tolerances, undermining the precision required in the industry. Lubricating moving parts with manufacturer-recommended oils helps minimize friction and prolongs the lifespan of these crucial components.

Implementing a scheduled maintenance program helps ensure no part of the live tooling system falls into disrepair. A good practice is to replace worn belts and bearings every six months or based on usage; tracking these intervals will help mitigate unexpected downtime. Additionally, keep an eye on coolant levels, which should remain consistent to facilitate effective heat dissipation during operations. Regularly updating software for tool adjustments can lead to better overall performance in precision swiss machining applications.

What Regular Maintenance Should You Consider for Longevity?

When it comes to maintaining live tooling equipment, establishing a regular cleaning routine is crucial for avoiding the buildup of chips and debris, which can significantly affect precision Swiss machining performance. You should ensure that coolant and lubrication systems are consistently checked. Insufficient lubrication can lead to wear and tear on the moving components of your CNC Swiss machining tools, which might result in costly repairs and downtime. Perform inspections every few weeks to identify potential issues before they escalate.

Additionally, calibrating your equipment is equally important for sustaining accuracy over time. Regularly checking the alignment and positioning of your live tooling can help preserve tight tolerances and overall quality of your machined parts. Implementing an inspection schedule that aligns with industry standards, such as those set by the ISO 9001 quality management systems, will not only enhance equipment reliability but also optimize productivity. Taking these proactive maintenance steps minimizes operational disruptions and can boost your machining efficiency significantly.

Real-World Applications of Live Tooling

Live tooling proves essential in various industries where precision and efficiency matter. In the aerospace sector, manufacturers utilize CNC Swiss machining to create complex parts that require both milling and turning features within a single setup. This eliminates unnecessary tool changes and reduces overall machining time, leading to higher throughput. For example, companies often report reductions in cycle times by as much as 30%, enabling them to meet stringent delivery schedules while maintaining tight tolerances on critical components.

The medical device industry also reaps significant benefits from precision Swiss machining. Here, equipment must meet rigorous regulatory standards while being produced with unparalleled accuracy. Live tooling facilitates the creation of intricate features on components like surgical instruments, combining multiple machining operations into one. This streamlined approach can improve production rates and minimize waste, aligning with best practices in lean manufacturing. More efficient workflows directly contribute to healthier profit margins, making investments in live tooling strategies increasingly attractive for these manufacturers.

Which Industries Benefit Most from Live Tooling Strategies?

CNC Swiss machining offers a strong advantage in industries requiring tight tolerances and intricate designs, such as aerospace and medical device manufacturing. For aerospace applications, components like fuel injectors and turbine blades benefit from precision Swiss machining, where even the slightest error can lead to safety concerns. Companies in this sector have reported up to a 30% reduction in machining time when they adopt live tooling strategies alongside traditional turning processes.

The automotive industry has also seen significant advantages from integrating live tooling. With the push for lightweight, complex parts, manufacturers can create everything from engine components to gear assemblies in a single setup. This not only minimizes handling times but also improves overall part accuracy. By embracing these precision techniques, automotive players can achieve efficiency gains of nearly 25%, highlighting how tailored tooling approaches can streamline production while meeting stringent quality standards.

3 Essential Tools for Effective Live Tooling

When diving into effective live tooling, having the right equipment on hand can make all the difference. A quality live tool holder allows for robust integration of both drilling and milling operations within a single machine setup. For instance, using a tool holder designed specifically for CNC Swiss machining can significantly reduce setup times and enhance part accuracy. With the ability to switch multiple tooling options quickly, operators can maintain a smooth workflow, cutting down on unnecessary downtimes that often plague traditional machining methods.

Equipping your operation with precision live tools ensures optimized performance and longevity in demanding environments. Consider the benefits of investing in high-precision collets and modular tooling attachments. These components help guarantee exact fits and engagements for your workpieces. For example, manufacturers that adopt precision Swiss machining often report up to a 30% increase in machining efficiency. Regular training on the latest tools and techniques also empowers machinists, ultimately leading to improved output and reduced scrap rates in production environments.

How Can the Right Tools Improve Your Machining Process?

Utilizing the right tools is vital for enhancing the efficiency and accuracy of your machining process. For instance, specialized tools tailored for CNC Swiss machining can significantly reduce cycle times. A study by the National Institute of Standards and Technology indicates that precision-enhancing tools can improve dimensional accuracy by up to 15%. Switching to high-performance cutting tools allows for faster feed rates and minimizes tool wear, promoting longer service intervals. This not only maximizes uptime but also contributes to lower overall production costs.

When choosing tools for precision Swiss machining, take advantage of advanced features like programmable spindle speeds and synchronized motion control. These capabilities streamline operations, allowing for complex parts to be machined in fewer setups, thus increasing throughput. Implementing a tooling strategy that incorporates modular tool holders can be a game changer for flexibility and responsiveness to design changes. Ultimately, investing in quality tooling can lead to more efficient workflows and enhanced product quality, yielding substantial long-term benefits for your business.

Analyzing Cost-Benefit of Live Tooling

Calculating the cost-benefit of implementing live tooling in CNC Swiss machining operations often reveals significant advantages. For example, a study showed that manufacturers who invested in these capabilities saw a 30% reduction in cycle times while simultaneously improving part accuracy. This combination can translate into lower overall production costs, allowing for increased competitiveness in precision Swiss machining markets.

Adopting live tooling can also lead to less machine downtime and higher throughput. Many facilities report a 20% increase in output after integrating live tooling into their workflow. This strategy not only speeds up the machining process but also minimizes the need for secondary operations, saving both time and resources. Conducting a detailed analysis of your current processes and exploring potential live tooling setups could yield beneficial insights for future cost savings and productivity enhancements.

What Financial Impact Can Live Tooling Have on Your Business?

Investing in live tooling can have a significant financial impact on your business. Operations that incorporate live tooling can boost productivity by up to 25%. For instance, a precision Swiss machining company that previously relied on separate setups for milling and drilling saw a 30% reduction in machining time after integrating live tooling into their CNC Swiss machining processes. Such efficiency not only shortens lead times but also improves throughput, allowing shops to take on more projects without increasing overhead costs.

Moreover, the upfront investment in live tooling is offset by reduced labor costs and less material waste. With the capability to perform multiple operations in a single setup, companies can minimize the need for handling and moving parts between different machines. This streamlined process results in a more efficient workflow and reduces the risk of errors associated with part transfers. For companies considering this approach, analyzing the return on investment over a year can reveal potential savings, making it an attractive option for those looking to enhance their operational capabilities.

FAQS

What is live tooling in Swiss machining?

Live tooling refers to the use of rotating tools that can perform various operations on a workpiece while it is being held in the machine, allowing for more complex machining processes without the need to reposition the part.

How often should I perform maintenance on my live tooling equipment?

It's best to follow the manufacturer's recommendations, but generally, a routine maintenance schedule every few months should keep your live tooling equipment in top shape. Regular checks can help catch any issues before they become major problems.

Which industries are most likely to benefit from live tooling strategies?

Industries such as automotive, aerospace, medical devices, and electronics often reap the benefits of live tooling strategies, as they require precision and efficiency in producing complex components.

What are some essential tools for effective live tooling?

Three essential tools for effective live tooling include high-quality live toolholders, precision cutting tools, and advanced control software, all of which can help optimize your machining process and improve overall productivity.

How can live tooling impact my business financially?

Live tooling can significantly reduce production time and costs by allowing multiple operations to be performed in one setup, leading to increased efficiency, lower labor costs, and improved product quality, which can all positively affect your bottom line.